In plumbing and automotive contexts, self-fusing tape serves as an effective tool for sealing leaks in hoses and pipes. Its ability to conform to different shapes ensures a tight seal, thereby preventing leaks from escalating into more significant issues.

Material Choices and Construction

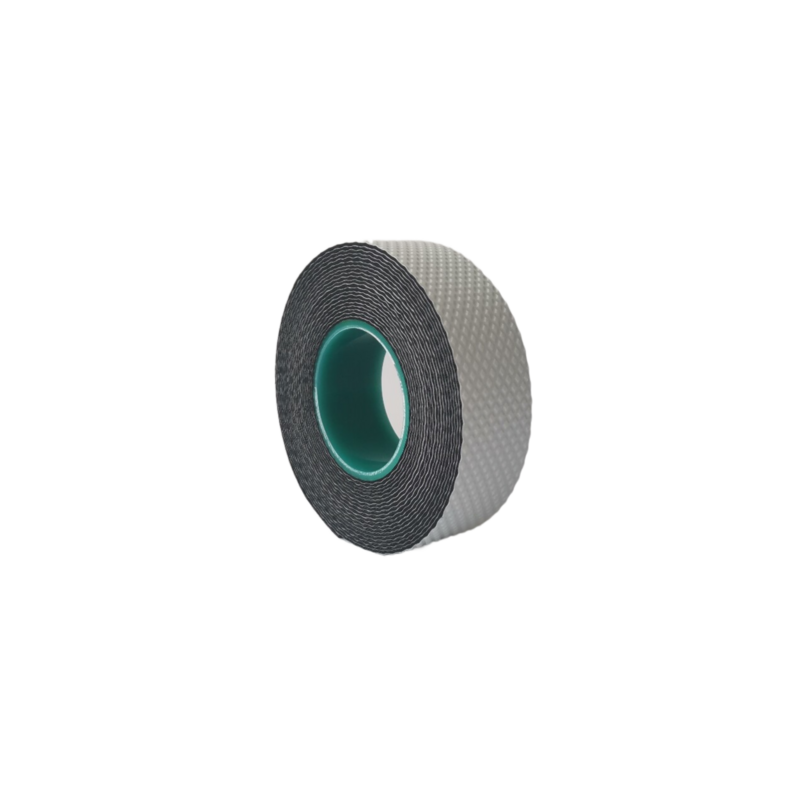

diall self amalgamating tape. Unlike traditional adhesive tapes, self-amalgamating tape does not require any additional adhesive to create a bond. Simply stretch and wrap the tape around the surface you wish to seal, and let the material fuse to itself to create a secure seal. This makes it a convenient and hassle-free option for quick repairs and emergency situations.

diall self amalgamating tape. Unlike traditional adhesive tapes, self-amalgamating tape does not require any additional adhesive to create a bond. Simply stretch and wrap the tape around the surface you wish to seal, and let the material fuse to itself to create a secure seal. This makes it a convenient and hassle-free option for quick repairs and emergency situations. Not all butyl rubber tapes are created equal. Suppliers may offer various types of butyl rubber tape with different properties and qualities. When selecting a supplier, it is essential to ensure they offer a variety of products that meet specific project requirements. Look for tapes with certifications that confirm their quality standards, such as ISO or ASTM certifications. Quality materials will often reflect in the overall performance and durability of the tape.

butyl rubber tape supplier

Essential Components and Their Roles

butyl rubber adhesive tape. Wrapped around pipe threads before assembly, it ensures a tight seal against leaks in pressurized systems. Its stretchability allows it to conform to the irregularities of the threads, creating a reliable barrier against fluid escape.

butyl rubber adhesive tape. Wrapped around pipe threads before assembly, it ensures a tight seal against leaks in pressurized systems. Its stretchability allows it to conform to the irregularities of the threads, creating a reliable barrier against fluid escape.

3. Sealing moisture-proof performance: the main material of this product is silicone rubber. Water vapor will not penetrate through silicone tape. It has excellent moisture-proof performance and realizes effective insulation;

several types of polyethylene film tape in various thicknesses and densities. Tape thickness is measured in mils — one mil is one one-thousandth of an inch. Simply choose the tape that works best for your application.

3. Temporary Repairs For quick fixes, red insulation tape can serve as an effective temporary solution. Whether it's securing a loose wire or insulating a damaged section of cable, the tape can be used in emergencies until a more permanent fix can be implemented.

This tape is easy to use, sticks to itself well and is available in convenient, 6 metre long rolls.

Single-side butyl tape works great when you need to bond two objects together whereas the latter can be used as a sealant or gasket. Plus, it's also available in various colors that make certain applications even easier!